Air To Air Heat Exchanger

Applications

Air to Air gas cooling system for

- Sponge iron kilns

- Arc furnaces

- Cement plant

- Rolling Mills

- Process plants

- Various dedusting system of high temperature

Special feature

Compact design

- Vertical tube arrangement to eliminate dust buildups

- Low pressure drop

- Effective cooling system ~1000°c to 120°c

- Easy to install

- Low maintenance

- Low operating power

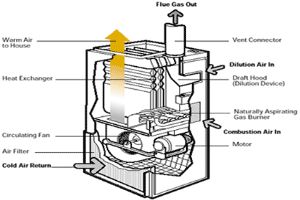

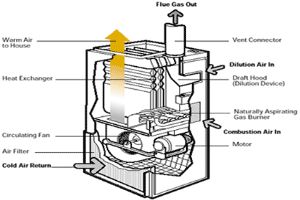

System Description

An air to air type of Heat Exchanger which has low running cost, easy to clean, easy to maintain and is 100 % reliable for cooling high temperature fine gases. Its design is compact and modular, easy to install and economical to run. Added advantage, is it provides clean hot air, which can be used in the process (material drying etc.) thereby making its operation commercially profitable. The heat exchanger has been designed in such a way that it can be run for 24 hrs.

The Air-to-Air Heat Exchanger reduces both the temperature and the dust

loading of the excess gas to the dust collecting system,thereby lowering the gas volume to be handled and

increasing the life of the filter bags. This also permits the vent fan to operate at reduced speed and

corresponding lower power consumption.

During upset clinker cooler

operating conditions, the Air-to-Air Heat Exchanger aids in the protection of the

downstream equipment within the specified design temperature limits. This is

accomplished without introduction of dilution air or water spray systems.

In most cooler vent systems where there is no heat exchanger ahead of the dust

collector, numerous problems are experienced with burning filter bags, unstable

kiln hood draft control, and limited vent system capacity due to the introduction of

dilution air. With the Air-to-Air Heat Exchanger, these problems are essentially

eliminated.

Stay Up to Date With Whats Happening