Electrostatic Precipitators Manufacturer

HIMENVIRO has installed numerous electrostatic precipitators in various fields of application. We have built more than 200 precipitators within last 5 years. The design of our Electrostatic Precipitator has evolved and been refined over the years to keep with the ever stricter and more stringent pollution control norms of the government

Applications

- Captive boilers handling various fuel mix

- Coal, Bagasse, Rice Husk, pet coke, Lignite Biogas, Sunflower etc.

- Production plants for cement, limestone and gypsum kilns, mills, driers and coolers

- Sponge Iron Plants

- Steel plants

- Lime & Dolomite Kilns

- Paper plants

- Aluminum plants

- Process plants & Many more

Special design features

- Modeled ESP's to ensure proper gas distribution inside ESP

- Rigid Multi spike Discharge electrode for steady corona generation & ideal for high resistive dust.

- Sigma profile Collecting electrode ensuring rigidity & quiescent zone to minimize re-entrainment.

- Suitable for high applied Kv-110 Kv (Peak)

- Microprocessor based rapping control system which is in-built with TR controller

- Penthouse design ESP, to ease maintenance under all-weather condition

- Pressurized air heating system to optimize operating power consumption & enhance longevity of insulators

- Availability of ESP is near to cent %.

- Opacity based control system.

The salient features of the ESP's we offer include:

- Horizontal and vertical flow precipitators.

- Designs for gas volumes, from as little as 10000 m3/hr. to 20,00,000 m3/hr.

- Hot gas designs for operation at temperatures above 500oC.

- ESPs for diverse applications like corrosive gas, tar and other difficult material, etc.

- Expertise of both bottom as well as top rapping.

Overview

Introduction to Precipitators

An electrostatic precipitator is a large, industrial emission-control unit. It is designed to trap and remove dust particles from the exhaust gas stream of an industrial process. Precipitators are used in these industries:

- Power/Electric

- Cement

- Chemicals

- Metals

- Paper

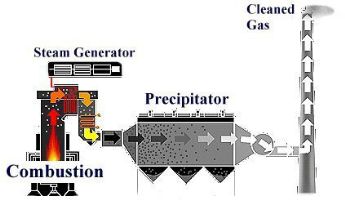

In many industrial plants, particulate matter created in the industrial process is carried as dust in the hot exhaust gases. These dust-laden gases pass through an electrostatic precipitator that collects most of the dust. Cleaned gas then passes out of the precipitator and through a stack to the atmosphere. Precipitators typically collect 99.9% or more of the dust from the gas stream.

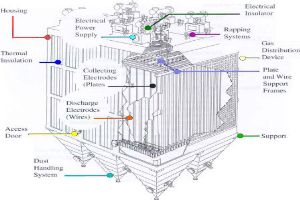

electrostatic precipitatorPrecipitators function by electrostatically charging the dust particles in the gas stream. The charged particles are then attracted to and deposited on plates or other collection devices. When enough dust has accumulated, the collectors are shaken to dislodge the dust, causing it to fall with the force of gravity to hoppers below. The dust is then removed by a conveyor system for disposal or recycling.

Depending upon dust characteristics and the gas volume to be treated, there are many different sizes, types and designs of electrostatic precipitators. Very large power plants may actually have multiple precipitators for each unit.

Basic principles

Electrostatic precipitation removes particles from the exhaust gas stream of an industrial process. Often the process involves combustion, but it can be any industrial process that would otherwise emit particles to the atmosphere. Six activities typically take place:

- Ionization - Charging of particles

- Migration - Transporting the charged particles to the collecting surfaces

- Collection - Precipitation of the charged particles onto the collecting surfaces

- Particle Dislodging - Removing the particles from the collecting surface to the hopper

- Particle Removal - Conveying the particles from the hopper to a disposal point

The major precipitator components that accomplish these activities are as follows:

- Discharge Electrodes

- Power Components

- Precipitator Controls

- Rapping Systems

- Purge Air Systems

- Flue Gas Conditioning

Stay Up to Date With Whats Happening