Reverse Air (R/A) Baghouses (aka Reverse Gas)

Electro-Plus Hybrid Filter-The Future

HIMENVIRO has a significant amount of operating experience with large reverse gas type fabric filters for Cement Kiln and Ferro alloys Furnace lime kilns and metallurgical processes. The Reverse Air Bag House (RABH) is a custom-built filter, designed for cleaning gases with typically high flow rates and high temperatures.

HIMENVIRO RABH have been designed to clean emissions from various industrial processes and handle a wide range of gas volumes from 50,000 m3/hr. to more than 15,00,000 M3/hr. Depending upon the duct characteristics, HIMENVIRO offers the most economical and efficient cleaning method to minimize pressure drop across the bag house.

The typical HIMENVIRO RABH is modular in construction, the modules being set in pairs, this construction and operation of the units not only offers control on velocity profiles, but also facilitates on-line maintenance. Each module can be isolated for inspection or maintenance by closing the inlet, outlet and reverse air damper, while other modules are in operation. The units - being custom built and voluminous - are dispatched knocked down to structural and panels.

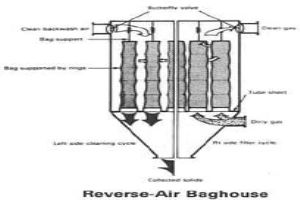

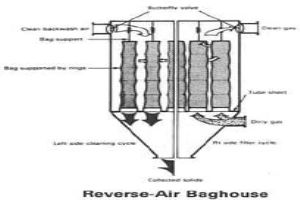

Reverse Air (R/A) Baghouses (aka Reverse Gas)

In reverse-air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse

and suspended from an adjustable hanger frame at the top. Dirty gas flow normally enters the baghouse and passes through the

bag from the inside, and the dust collects on the inside of the bags.

Reverse-air baghouses are compartmentalized to allow continuous operation. Before a cleaning cycle begins, filtration is stopped in the compartment to be cleaned. Bags are cleaned by injecting clean air into the dust collector in a reverse direction, which pressurizes the compartment. The pressure makes the bags collapse partially, causing the dust cake to crack and fall into the hopper below. At the end of the cleaning cycle, reverse airflow is discontinued, and the compartment is returned to the main stream.

The flow of the dirty gas helps maintain the shape of the bag. However, to prevent total collapse and fabric chafing during the cleaning cycle, rigid rings are sewn into the bags at intervals.

Space requirements for a reverse-air baghouse are comparable to those of a shaker baghouse; however, maintenance needs are somewhat greater.

In many industrial plants, particulate matter created in the

industrial process is carried as dust in the hot exhaust gases. These dust-laden gases

pass through an electrostatic precipitator that collects most of the dust. Cleaned gas

then passes out of the precipitator and through a stack to the atmosphere. Precipitators

typically collect 99.9% or more of the dust from the gas stream.

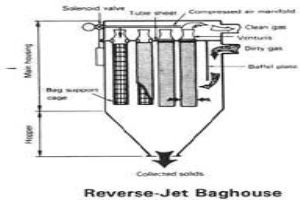

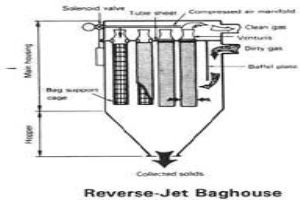

Pulse Jet Baghouses (aka Reverse Jet)

In reverse-pulse-jet baghouses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the baghouse. Dirty gas enters from the bottom of the baghouse and flows from outside to inside the bags. The metal cage prevents collapse of the bag.

Bags are cleaned by a short burst of compressed air injected through a common manifold over a row of bags. The compressed air is accelerated by aventuri nozzle mounted at the reverse-jet baghouse top of the bag. Since the duration of the compressed-air burst is short (0.1s), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust cake, and the dislodged dust falls into a storage hopper below.

Reverse-pulse-jet dust collectors can be operated continuously and cleaned without interruption of flow because the burst of compressed air is very small compared with the total volume of dusty air through the collector. Because of this continuous-cleaning feature, reverse-jet dust collectors are usually not compartmentalized.

The short cleaning cycle of reverse-jet collectors reduces recirculation and redeposit of dust. These collectors provide more complete cleaning and reconditioning of bags than shaker or reverse-air cleaning methods. Also, the continuous-cleaning feature allows them to operate at higher air-to-cloth ratios, so the space requirements are lower.

This cleaning system works with the help of digital sequential timer attached to the fabric filter. this timer indicates the solenoid valve to inject the air to the blow pipe.

Stay Up to Date With Whats Happening